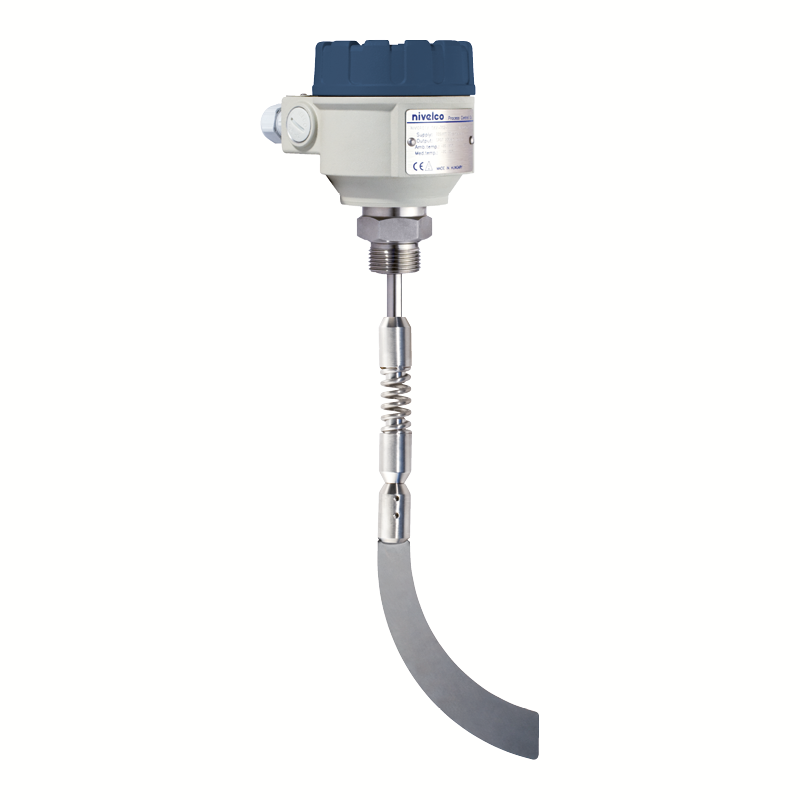

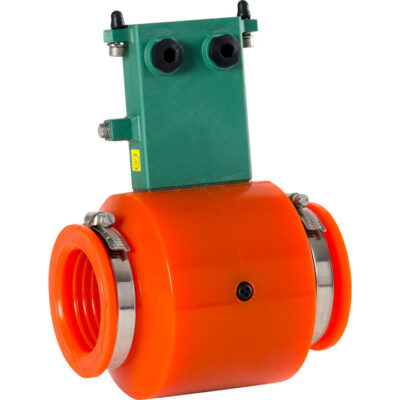

Rotary Paddle / NIVOROTA®

GENERAL DESCRIPTION

NIVOROTA rotary paddle level switches detect the level of lumpy substances, powders, grains, or granules. Mounted onto tanks, silos, or hoppers, it monitors and controls the filling and dumping of stored materials, such as stone, ash, sand, coal, feed, beet slices, etc.

A small electric motor drives the paddle, which rotates freely in the absence of material. When the material reaches the paddle, the motor is switched off, and the output switch is triggered. When the material level drops, the paddle is free to spin again, the motor is reactivated, and the switch returns to its original state. The NIVOROTA E-700 & E-800 series Rotary Paddle Level Switches provide all the advantageous features of the previous series in one unit. Dust Ex versions are available for use in hazardous environments.

Description

PRODUCT PROPERTIES

- Plastic or aluminum housing

- Long service time

- Motor shut-off feature

- Flexible coupling

- Solid rod or flexible cable extension (0.3–3 m)

- Sealed bearings

- High-temperature version

- Dust-Ex variants available

- High or low fail-safe

- Feed, coal, sand, rocks, limestone, metals, rubber

- Rotary force independent of the supply voltage

- Low supply voltage is indicated by a blinking LED

APPLICATIONS

- Granular material and powder with minimum 0.1 kg/dm³ density

- Agriculture

- Construction materials

- Chemical industry

- Food and beverage

- Mining industry

- Paper mill

- Recycling

- Plastic industry

SPECIFICATION

| Power supply: | 24 VAC/DC, 120 VAC, 230 VAC |

|---|---|

| Ambient temperature: | −30°C…+60°C |

| Process temperature: | −20°C…+200°C |

| Process pressure: | up to 3 bar |

| Output: | relay (SPDT) 250 VAC, 5A, AC1 |

| Process connection: | BSPT 1″, 1½”, mounting plate |

| Ingress protection: | IP67 |

| Approvals: | ATEX |

Additional information

| Weight | 5 kg |

|---|---|

| Dimensions | 30 × 100 × 100 cm |

Reviews

There are no reviews yet.